Testing

Tailored to the project and system requirements as well as customers' needs, test procedures are prepared and released by the Prime System Engineer in close coordination with the client.

Starting with the basic electrical safety test according to DGUV-3 (formerly BGVA3), different components and subsystems are commissioned and tested. This is followed by the Overall System Testing, where the interaction of all components and subsystems are finally verified.

With the Factory Acceptance Test (FAT), customer samples from test results are validated.

Overall System Testing

The interaction of all components and subsystems is assessed for overall system functionality. After all components and subsystems have been commissioned and tested, the Overall System Testing based on pre-defined test procedure takes place.

Depending on the scope of the project, the Overall System Testing may be clustered into two phases:

- Factory Testing

- On-Site Testing

Network Testing

Network performance is always important to the customer. Therefore network testing focuses on the user cases and the traffic profile described by the customer prior to the Network Design Phase. Following these performance tests, longer-term tests 24 or 48 hours with dedicated device and traffic monitoring are completed.

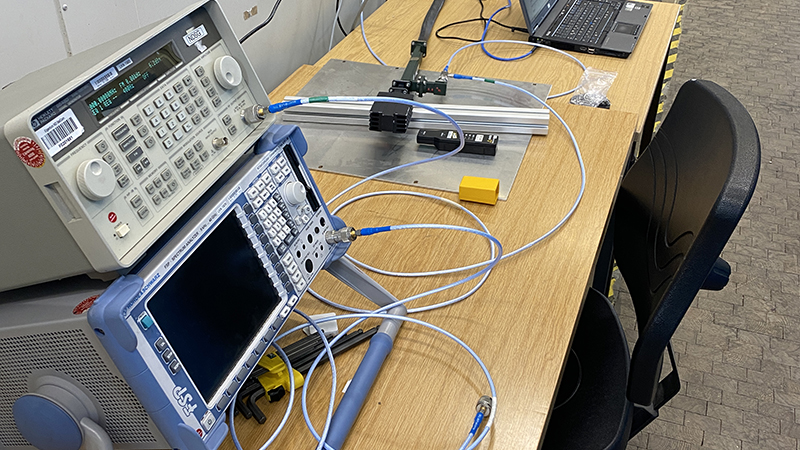

Radio Frequency (RF) Testing

RF testing mainly focuses on the satellite-link relevant parameters with the following tests:

- Receive path

- G/T

- Frequency stability

- Receive-level stability

- Transmit path

- Max. EIRP

- Spectrum density mask => min. HPA back off

- EIRP stability

- Frequency stability

- Phase noise

- Intermodulation